Fasteners and Machining: Integrating Precision and Strength in Manufacturing

Introducing the Details of Fasteners and Machining Processes for Optimum Performance

In the world of design and manufacturing, the option of fasteners and the complexities of machining procedures play an essential role in establishing the utmost performance and resilience of an item. From the relatively straightforward job of selecting the best kind of bolt to the complex precision machining methods used, every action in this process needs careful attention to information. As we start this expedition right into the world of bolts and machining, we will reveal the subtle yet essential elements that can dramatically affect the efficiency and high quality of the end product, clarifying the frequently forgotten aspects that can make all the distinction in attaining ideal performance.

Significance of Proper Bolt Option

Choosing the suitable fasteners is crucial in ensuring the architectural stability and durability of any type of mechanical assembly. Bolts play an essential role in holding parts with each other safely, with the right selection contributing significantly to the total performance and reliability of the setting up. When picking fasteners, factors such as product compatibility, ecological conditions, load-bearing capacity, and ease of installment have to be very carefully considered to assure ideal efficiency.

Incorrect bolt choice can lead to a variety of concerns, consisting of loosening, rust, and even structural failing. Utilizing bolts that are not fit to the details demands of the setting up can jeopardize its performance and position safety threats. Designers and designers have to carefully review the application requires and pick fasteners that satisfy or go beyond the necessary requirements and requirements.

Furthermore, the appropriate bolt option procedure entails evaluating the joint style, prepared for lots, resonance levels, and potential thermal growth or tightening to make certain that the picked bolts can withstand the operating problems effectively. By prioritizing appropriate fastener choice, makers can boost the top quality, resilience, and performance of their mechanical assemblies.

Types and Qualities of Fasteners

An important element of mechanical assemblies exists in recognizing the varied types and unique features of bolts utilized in numerous commercial applications. Fasteners are crucial elements that hold structures with each other, making sure stability and capability.

Screws are threaded bolts that are typically made use of to join 2 or more elements with each other. Nuts are internally threaded bolts that mate with screws to hold elements with each other. Washers are thin plates that disperse the load of a fastener, protecting against damage to the product being fastened.

Comprehending the attributes of each kind of fastener is necessary for picking the appropriate one for a certain application, making sure ideal performance and dependability of the mechanical assembly. Fasteners and Machining.

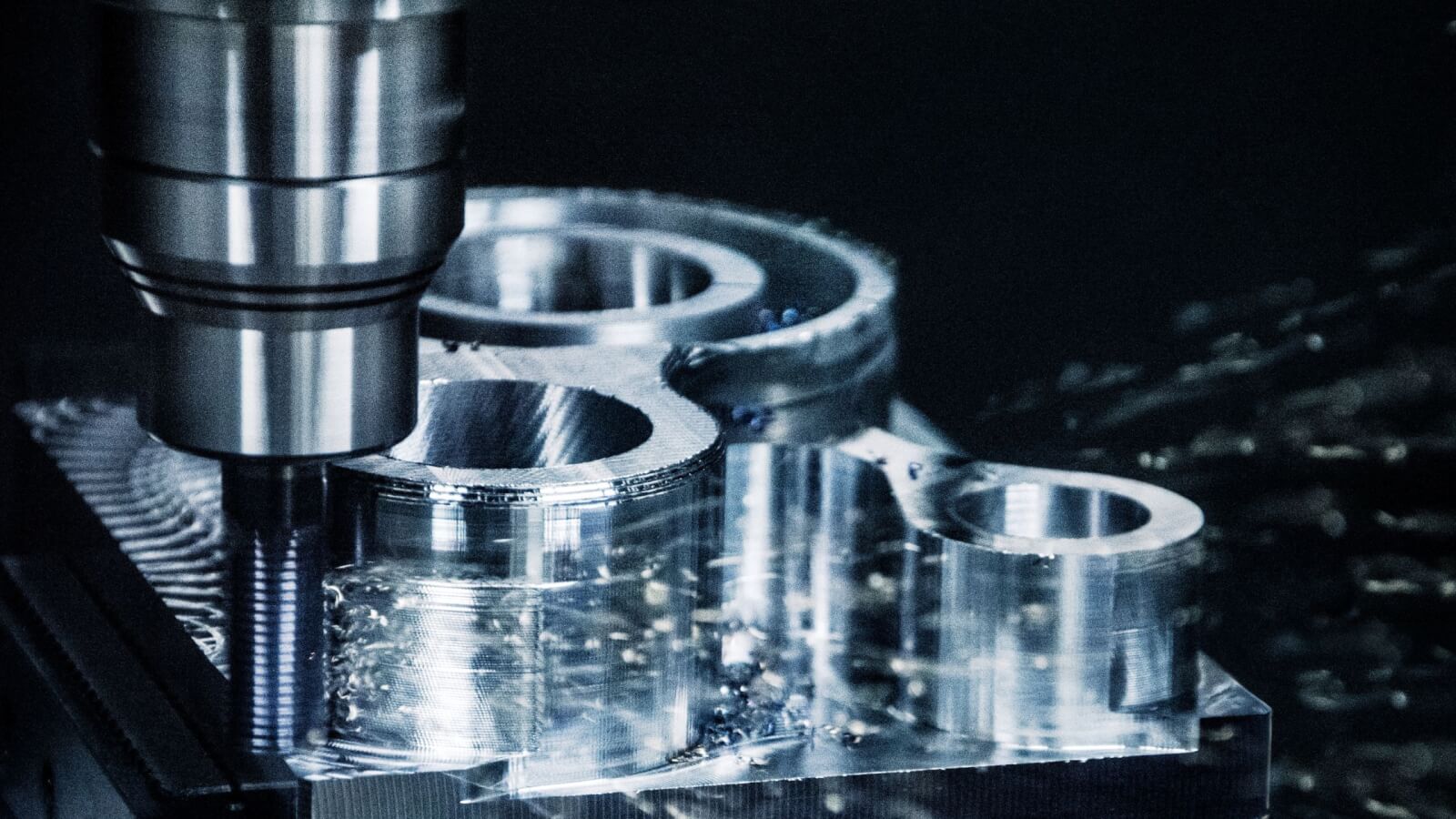

Accuracy Machining Strategies for Performance

The detailed layout needs of different fasteners demand employing accuracy machining methods Read Full Article for optimal performance in manufacturing procedures. One of the primary strategies used in accuracy machining is Computer Numerical Control (CNC) machining, which makes it possible for high levels of precision and repeatability in the manufacturing of fasteners.

In addition to CNC machining, other precision strategies such as grinding, milling, and turning are generally used to attain the tight tolerances needed for fasteners. These methods permit producers to create bolts with smooth surface areas, accurate measurements, and high architectural integrity. By using accuracy machining techniques, makers can boost the quality of fasteners, minimize material waste, and boost overall production performance. The use of sophisticated machining procedures aids make certain that bolts meet industry requirements and client assumptions for performance and dependability.

Elements Affecting Machining Process Efficiency

Numerous variables play a substantial role in determining the performance of machining processes in the manufacturing of bolts. Maximizing these parameters based on the specific requirements of the fastener being produced is key to achieving accurate and affordable machining.

Machine strength and stability also play a critical function in identifying machining procedure performance. An experienced operator can make real-time changes, troubleshoot problems efficiently, and make certain that the machining process runs efficiently, eventually affecting the final quality of the bolt.

High Quality Control Steps in Manufacturing

Aspects influencing machining process performance, such as cutting tool selection and machine security, straight influence the execution of top quality control procedures in production. Quality control actions are crucial in making certain that items fulfill the needed standards and requirements. In the production procedure, different techniques are used to keep high quality criteria. Examination and testing play an important role in recognizing any kind of variances from the desired outcome. Normal maintenance of machining equipment is additionally essential to maintain quality control. Calibration of equipments and tools is necessary to make certain specific and original site precise manufacturing processes. In addition, executing standard operating procedures and protocols can assist in maintaining uniformity and high quality throughout the manufacturing line. Quality control gauges not only concentrate on the end item however additionally on every stage of the production process to protect against mistakes and problems. By sticking to strict top quality control steps, suppliers can enhance client complete satisfaction, construct a credibility for integrity, and ultimately accomplish optimal performance in their machining processes.

Verdict

To conclude, selecting the right fasteners and utilizing precision machining methods are necessary for optimum efficiency in making procedures. Recognizing the types and attributes of bolts, together with aspects affecting machining process performance, can result in enhanced effectiveness and quality control steps. By taking notice of these complexities, producers can achieve higher levels of performance and reliability in their items.

In the world of design and production, the selection of fasteners and the details Learn More of machining procedures play an essential function in identifying the ultimate efficiency and durability of an item (Fasteners and Machining). One of the main techniques made use of in accuracy machining is Computer Numerical Control (CNC) machining, which enables high degrees of accuracy and repeatability in the production of bolts. The use of sophisticated machining processes aids make sure that fasteners fulfill industry requirements and customer assumptions for performance and reliability

In verdict, selecting the right bolts and utilizing accuracy machining methods are essential for optimum performance in making processes. Recognizing the kinds and attributes of fasteners, along with variables influencing machining procedure performance, can lead to boosted efficiency and top quality control steps.